3. Characteristics: Processing ability: 70–460 t/h Feeding granularity: 100–800 mm Dimensions: 2100×2450×2000–2500×4360× 2400 mm Applied material: coal, pebble, perlite, limestone, dolomite, etc Technical data:Working principle: Toothed roll crusher is mainly composed of driving tooth, reducer, hydraulic coupler, electromotor, motor

Learn More

8/20 · The structure of the single roll crusher is shown in Figure 3. The crushing mechanism consists of a rotating roll 1 and a jaw plate 4. The jaws are mounted on a bolt with

Learn More

Material is feeding from the feeding mouth above. Through two opposite rotating grinding roller, with the aid of friction and gravity, the

Learn More

12/28 · About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features

Learn More

Main parts】Bearing box, roll shell, bearing housing, adjusting rod, motor, carrier, fixed roller, movable roller and safety spring, etc. 【Working Principle

Learn More

Aug 11, The Working Principle of Roll Crusher. Double-roll crusher can be divided into high speed and low speed double-roll crusher according to the revolving speed of roller; According to the installation methods of roller, it can be divided into two kinds: a roller bearing is active, and the other bearings is fixed and two roller bearings are active

Learn More

principle of roll crusher Roll Crusher Manufacturers,Suppliers & Dealers in Roll Crusher Double Roller Crusher Double Roll Crusher. Roll Crusher Working Principle hotelsanfelip

Learn More

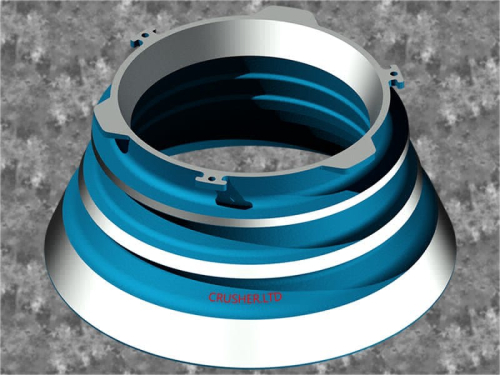

Roll Crusher Working Principle - manufacturer, factory, supplier from China Hot Sale Concrete Impact Crusher With High Efficiency Cone Crushers are Suitable for all Crushing Needs SANLAND ST-0100 cone crusher Sanland Cone Crusher is your needs

Learn More

used vsi crushers for sale,vsi crusher working principle. vsi crusher & vsi crusher application:sand making plant,stone shaping.★ TEL:+86-21-58386189

Learn More

8/10 · 1. the series of roll crusher is mainly composed of the roller, the roller support bearings, compaction and adjusting device and driving unit and other parts. 2, the adjustment of the discharging granularity: with a wedge or gasket between the two roller adjustment device, adjusting bolt, wedge at the top of the device when the adjusting bolt will wedge pulled up,

Learn More

Roll crushers are secondary crushers used for size reduction of solids. They have reduction ratio of 4:1. They are primarily used in Coal and building materi

Learn More

The working principle: The roll crusher will be broken material feeding the mouth fall between two rollers, extrusion, finished product material nature. When the weather is good or not broken, the roll crusher roller but by hydraulic cylinder or the role of the spring automatic, make the roll gap

Learn More

The working principle: The roll crusher will be broken material feeding the mouth fall between two rollers, extrusion, finished product material nature. When the weather is good or not broken, the roll crusher roller but by hydraulic cylinder or the role of the spring automatic, make the roll gap

Learn More

Double roller crusher working principle.The mode of operation of roll crushers is extremely simple,the standard spring rolls consisting of two horizontal

Learn More

How Roll Crushers Work Whether the application requires a single-stage or two-stage crusher, the forces necessary to perform the crushing remain the same: a combination of impact, shear and compression. The impact force occurs as the material enters the crusher and is impacted by the rotating roll.

Learn More

Relative rotation of the two roll gap to a certain extent, change the gap, can maximum discharging granularity control products. Double roll crusher is the use

Learn More

2022/1/21 · The roll crusher working principle is a physics of angular relations. When the material is too large to pass the rollers, it will not be crushed into a small particle. In this case, the material must have a certain amount of debris. In such cases, the roll crusher works

Learn More

What Is A Jaw Crusher MEKA Crushing Equipment / the working principle of jaw crushers all jaw crushers feature two jaws one of which is fixed while the other moves. the working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the jaws.

Learn More

Chapter Roll Crushers Roller Crusher. Chapter Roll Crushers Chapter 6 roll crushers sciencedirect figure 64 is a typical setup where ores crushed in primary

Learn More

THE MODE OF OPERATION. The crushing rolls are driven individually and direct- ly by means of electro-motors or with coupling and.

Learn More

OPERATION. Roll Crusher operation is based on the principle of continuous pressure generated between two counter-rotating rolls; allowing uninterrupted crushing

Learn More

China Single Roll Crusher Working Principle Manufacture, Visit Here to Find the Single Roll Crusher Working Principle That You are Searching for. Shenyang Sanland Mining Equipment Manufacture Co., Ltd. [Liaoning,China] Business Type: Manufacturer Main

Learn More

The slow roller's face width is sprung, so uncrushable objects can pass through without damaging the machine. The fast roller is fixed, not sprung. The

Learn More

The crushing mechanism consists of a rotating roll 1 and a jaw plate 4. The jaws are mounted on a bolt with a tooth bushing 2 on the core of the

Learn More

The crushing mechanism of smooth roll crusher is mainly is squashing, the two both have the function of grinding. Chapter 6. Roll Crushers #2fishygirl on Scribd

Learn More

The crushing-pressure exerted by the opposing roll-surfaces during the angle of nip is instantly released and ceases when the rock-fragments

Learn More

Copyright © 2021 PEAKEDNESS Inc. All rights reserved.