Jaw Crusher Liners. Selecting the right jaw profile can not only significantly improve jaw crusher performance but also secondary crushing efficiency by generating more accurate and more

Learn More

crushtechs specialized in all kinds of crusher and crusher parts.cone liners, jaw liners, cone mantle liner, concave liner, jaw plate, impact crusher parts,

Learn More

They only register compressive/tensile forces. The liner material is manganese alloy steel, commonly used for crusher liners, with 1.2% C, 12.5% Mn, 0.6% Si and

Learn More

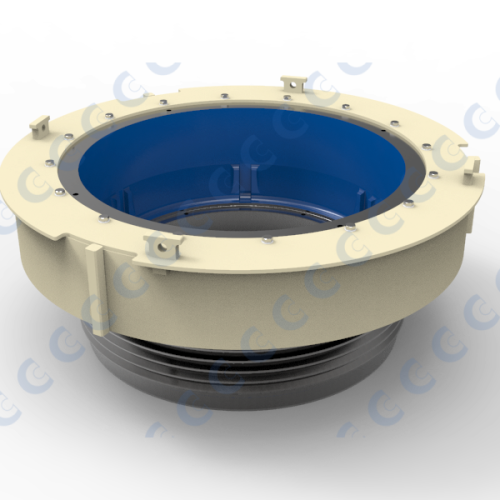

wear parts for all major makes and models of cone, jaw and gyratory crushers. Mantles and liners: ready-to-order or Custom-Engineered Accessories

Learn More

High and anti-slab teeth jaws; Toothed with smooth end jaws; Standard and Xtralloy premium alloys. Cone Crushers. MSS Can Help You Select Cone Crusher Liners

Learn More

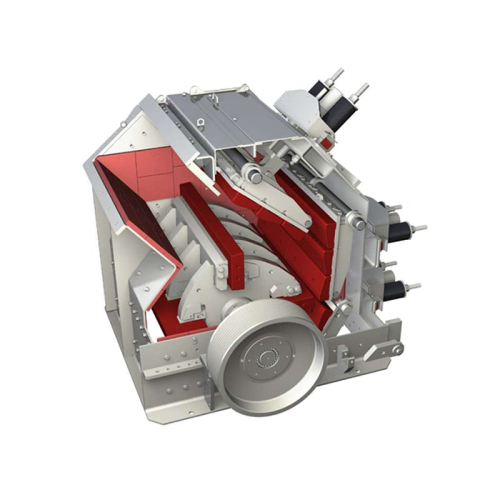

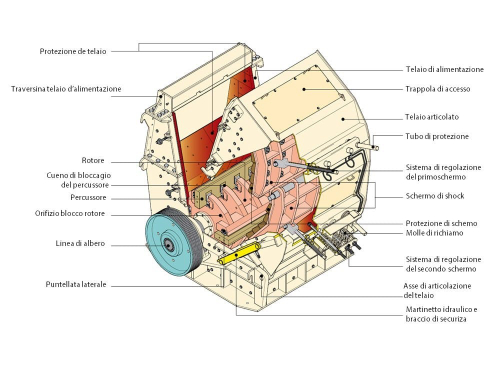

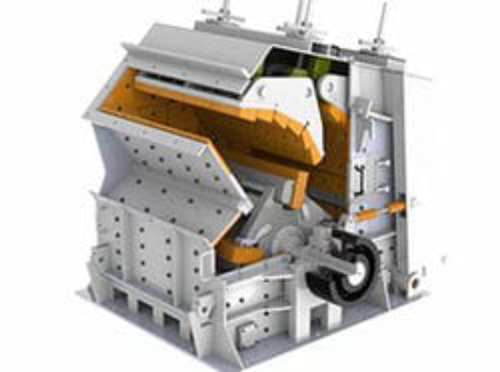

C Series jaw crushers have a strong pinned and bolted, non-welded frame construction and the highest power ratings in each size class, which brings benefits to stationary, underground and mobile crushing applications. They are designed to the highest safety standards to make the use and maintenance as easy as possible.

Learn More

Crusher Liners, CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators. We have over 30 years' experience supplying crushing wear parts to global mining and mineral processing, oil sands, steel, cement, power and aggregate customers.

Learn More

Welcome to the First Edition of the Finlay Crusher Wear Parts crusher tools E.G. Jaw liners are subject to numerous pressure and impact stresses.

Learn More

When do jaw crusher liners need to be replaced? 2022-07-28 11:09:00. SHARE TO: In the medium and fine crushing of ores, jaw crushers are often used. Among the moving parts of the stone crusher, the lining plate is the part that is in direct contact with the hard material, so it belongs to the wearing part of the crusher accessories. This is

Learn More

Australin Crushing & Mining Supplies are able to offer aftermarket Blow Bars & liner plates, we also have developed a range of impact bars to suit the

Learn More

Our jaw crusher plates, cast and machined chrome white iron protection covers and wear plates, chrome carbide overlaid plates/curves, and other parts are

Learn More

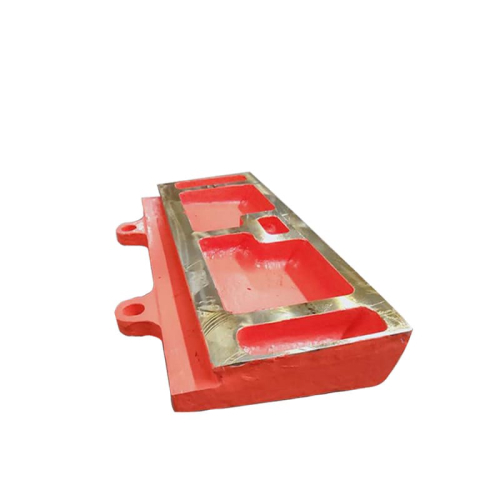

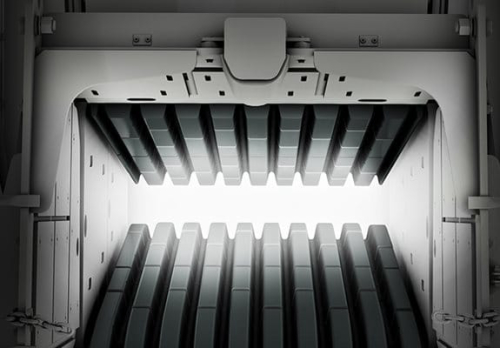

J aw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time.. A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw).Compression of material undergoing crushing in a jaw crusher is achieved when the

Learn More

We are the famous company in offering Jaw Crusher Liner Plate to our clients. This product is widely used in batching plant around the globe.

Learn More

You'll get wholesale jaw crusher liners that specializes in mining, with reinforced chassis, and run on more powerful engines. Whether you want to transport

Learn More

Resminer jaw crusher liners with the first-class quality of manganese steel have been verified in ISO quality standards. We produced our product using advanced machinery and technology that improves the efficiency of the production process. Resminer has the premium quality of jaw crusher liners made of the unique quality of manganese and alloy.

Learn More

CMS Cepcor® stock a wide range of cavity liner options for cone crushers along with many jaw plate tooth profile options for jaw crushers and various

Learn More

Spray Bed Liners in Hillsboro, OR. About Search Results. Sort:Default. Default; Distance; Rating; Name (A - Z) Sponsored Links. 1. Bob Top Canopies. Truck Caps, Shells & Liners Truck Accessories Truck Equipment & Parts (2) BBB Rating: A+. Website. 22. YEARS IN BUSINESS (503) 648-5903. 2505 SE 48th Ave.

Learn More

jaw liners crusher settings jaw liners crusher settings As a classic primary crusher with stable performances, Jaw Crusher is widely used to crush metallic and non-metallic ores as well as building aggregates or to make artificial sand. Input Size: 0-1020mm Capacity: 45-800T.

Learn More

El-Jay Rollercone Bowl Liner 2021-09-13 Rollercone Crusher Liner: Items: Concave, Mantle, Concave Ring, Concave Segment , Bowl Liner,Cone Liner,Arm Guard, Distribution Plate Casting Material: Austenstic Manganese Steel (Mn14, M14Cr2, Mn18Cr2, Mn22Cr2) Casting Method: Water Glass Sand

Learn More

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The capacity is primarily a function of: 1. crusher design characteristics such as width and depth of the crushing chamber, 2. open and closed side settings, 3.

Learn More

19/04/2022 · Hunan JY Casting manufactures crusher wear parts (cone crusher liners, crusher jaw plates, crusher blow bars), shredder wear parts (shredder hammer, grates, caps, anvils), mill liners (lifting plates, shell liners, end liners), and apron feeder pans for the most popular brands. Custom or OEM Wear Parts,

Learn More

30/08/ · Jaw Crusher Liners, Jaw crusher liners play an effective role in the crushing process. Both jaws contain different types of liners for crushing the hardest and abrasive materials. The liners are extremely sharps enough to crush the toughest and slippery rocks. Some liners have specially designed for slippery rocks.

Learn More

Jaw Crusher Liners Selecting the right jaw profile can not only significantly improve jaw crusher performance but also secondary crushing efficiency by

Learn More

Jaw crusher wear parts are designed for processing all rock types in surface and underground operations. Our offering consists of jaw plates such as different

Learn More

Through constant research and development, ACE have a history of designing wear products for cone liners, jaw liners and impact hammers, blow-bars and segment

Learn More

Crusher Wear Parts is an industry leader in supplying the best jaw liner parts for a specific application We offer OEM as well as specialty configurations. We have decades of experience in supplying wear parts to the aggregate and mining industries.::: Austenitic manganese steel is the industry standard material for jaw crusher liners.

Learn More

Copyright © 2021 PEAKEDNESS Inc. All rights reserved.