17/01/ · At this level Throw = OSS – CSS A crusher that has a 20cm throw is one where the mantle surface approaches and recedes from the concave through a distance of 20cm as

Learn More

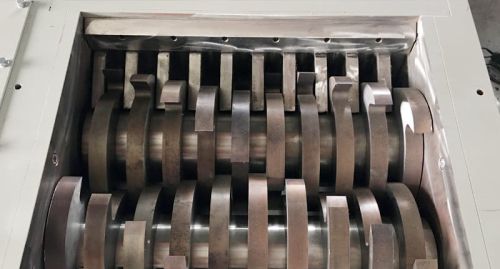

Contents · 1 Background history · 2 Industrial use · 3 Types of crushers. 3.1 Jaw crusher; 3.2 Gyratory crusher; 3.3 Cone crusher. 3.3.1 Compound cone crusher; 3.3

Learn More

Able to sling three regulated .50 caliber shots per fill, the Hammer utilizes Umarex's patent-pending Lightspeed™ valve created specifically to deliver jaw-dropping power. Crafted to throw 550 grain, .50 caliber slugs downrange at 760fps for an unheard of 700 FPE, and a 250gr slug at 1,000 fps—the Hammer has more than enough power to

Learn More

17/02/ · s is jaw throw, m; a is the nip angle; k is a material factor, 1.5 to 2.0 (includes your epsilon param) N is RPM; This form works out volume of one motion of the jaw, multiplies by

Learn More

It is equal to the CSS plus the throw of the swing stock. The dimension on the discharge end of the jaw liners are measured from Peak to Root. To measure the

Learn More

PE Jaw Crusher For Sale; Capacity: 110-1100 t/h, Customized Max. Feeding Size: 125-1200 mm Compressive strength: Less than 320 MPa Processed Materials: Granite, marble, basalt, limestone, quartz, river pebbles, iron ore, copper ore, etc. Application: Widely used for medium-sized crushing of ore and bulk materials in mining, metallurgy, construction, road, railway, water and chemical industries.

Learn More

DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with compressive strength below 320 MPa.DOVE Crushers are supplied in Stationary complex plant configuration, or in Portable and Mobile configuration.. Designed with optimum cavities and

Learn More

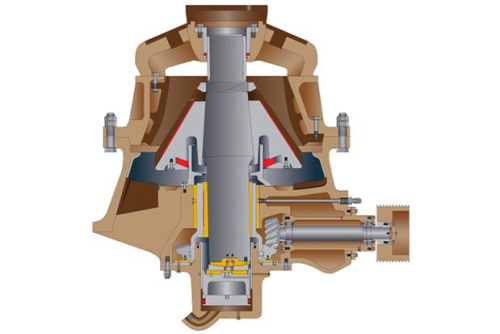

crusher can be varied in the field and some crushers are equipped with automatically controlled actuated for the automatic control of the set. The open- and closed-side sets and the gape are identified in Figure 5.1. The throw of the crusher is the distance that moving jaw moves in going from OSS to CSS. Throw = OSS-CSS.

Learn More

PE750 × 1060 jaw crusher characteristics and uses: PE-750 × 1060 jaw crusher is the common equipment of large and medium-sized mines a crushing maximum feed size of 630mm, motor power 110kw. Widely used in gravel pits, coal mines, roads, railways and other industries. Common hard rock, such as basalt, and other hard rock, such as granite

Learn More

This portable and lightweight (35 lbs.), is perfect for low volume metallurgical sample preparation or any small home laboratory a gold prospector would have in his garage. Crushing Rate: from 2.5″ rock to 3/8″ product = 150 lb/hour from 3/8″ rock to 20 mesh product = 50 lb/hour total from 2.5″ to 20 mesh in 2 passes = 40 lb/hr IN-STOCK - +

Learn More

The maximum amplitude of swing of the jaw, or "throw", is determined by the type of material being crushed and is usually adjusted by changing the eccentric. It varies from 1 to 7 cm depending on the machine size, and is highest for tough, plastic material and lowest for hard, brittle ore.

Learn More

Jaw crushers have a multitude of advantages, including: Can handle many different types of materials—from hard granite to reclaimed asphalt pavement (RAP) and more—without displaying as much wear and tear as primary impact-style crushers. Typically output minimal fine materials and dust. More efficient than primary gyratory crushers.

Learn More

The study showed that industrial jaw crushers are generally operated below capacity. parameter related to throw of the crusher.

Learn More

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER: A eccentricity of the shaft leads to increase in throw; hence,.

Learn More

Keywords: Design; Operations; Jaw crusher; Challenges; Crushing parameters eccentricity of the shaft leads to increase in throw; hence,.

Learn More

Offset ratio · throw · eccentric lobe · crushing machine · redesign. Disclosure statement. No potential conflict of interest was

Learn More

A higher eccentric throw means fewer crushing zones, so the journey through the crusher is quicker. The quicker the journey through the crusher, the greater its

Learn More

throw movement of adjustment of the vibratory displacement and vibratory velocity of the LCE by using phase angle materials by inclined vibratory conveyors 00Katalog Kap04 43-56 – Welcome to ROSTA makers of Dynamic

Learn More

the addition of an eccentric throw factor, is appli- cable to standard types of single-toggle or overhead eccentric jaw crushers as far as maximum capacity.

Learn More

Efficient Kinematics and Powerful. Better crushing performance also lies in good kinematic parameters. The MP PEV series jaw crusher uses a eccentric throw

Learn More

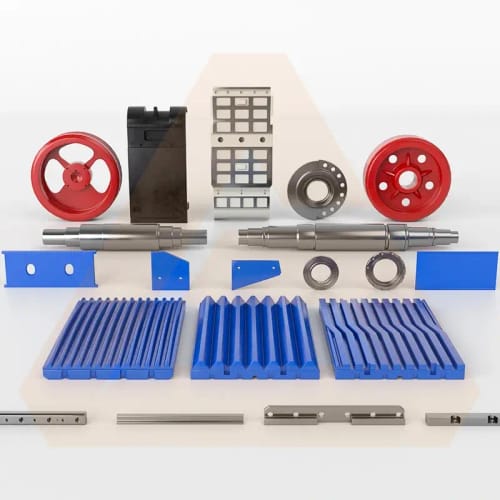

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

Learn More

Jaw Crusher Terminology The horizontal component of motion (throw) at the discharge point of the single-toggle jaw crusher is greater than the

Learn More

Series jaw crushers have a large eccentric throw coupled with a steep toggle plate angle that magnifies the effective stroke at the crusher discharge.

Learn More

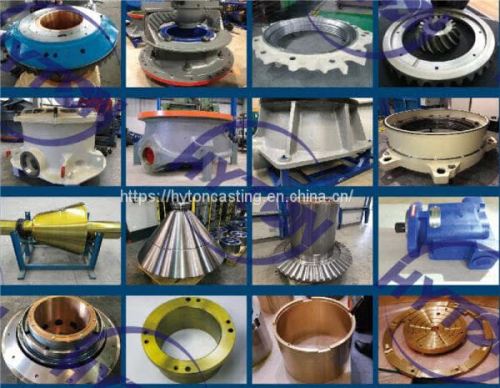

To reach a mutual advantage of our prospects, suppliers, the society and ourselves for Cone Crusher Throw, Jaw Crusher Efficiency, Gp300 Broken Wall, Crushing Mining Equipment Qld,Cone Crusher Components. Good quality and aggressive prices make our products get pleasure from a significant name all around the word. The product will supply to all

Learn More

21/11/ · Find the gape size when the capacity of jaw crushers is 5, the width of crusher is 3 and the closed single setting of jaw crusher is 6. This implies that; C JC = Capacity of Jaw

Learn More

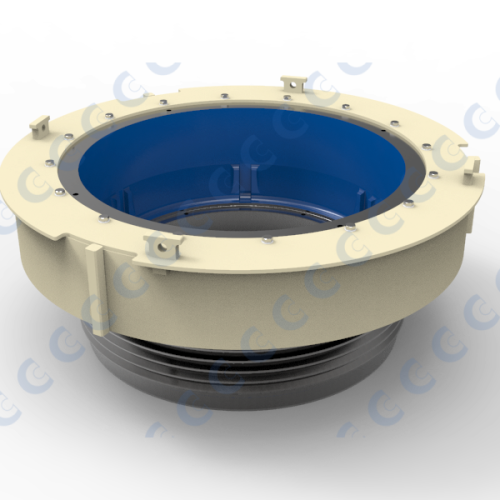

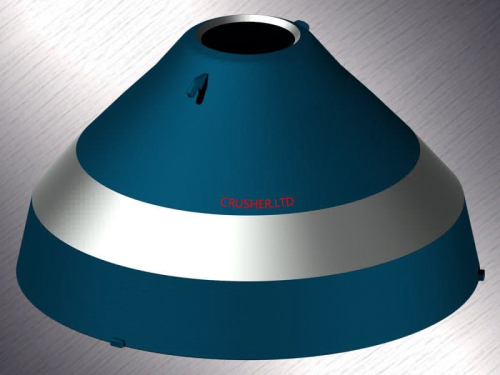

The eccentric throw is one of the most important parameters in defining the job that your cone crusher does. The mantle in a cone crusher spins in conical pendulum motion. That means it

Learn More

Copyright © 2021 PEAKEDNESS Inc. All rights reserved.