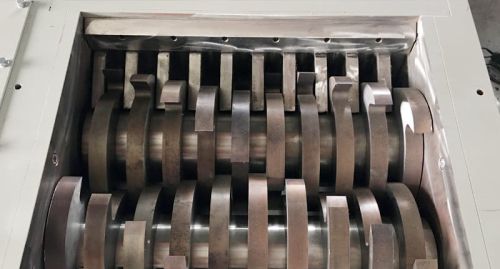

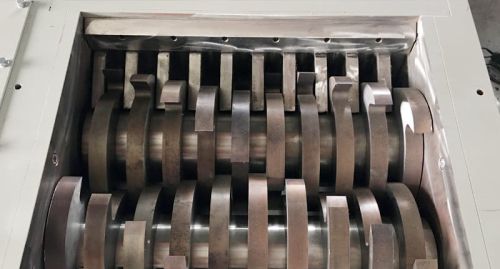

The actual crusher can be in the form of a cone, gyratory, impact, jaw, etc. – type machine. Common to all crushers is the requirement for lubrication,

Learn More

Petron's Crusher Spider Bushing Lubricant has been exclusively used to lubricate Tenova TAKRAF, Allis Chalmers, , gyratory crushers with sizes varying from 54"X74" to 63"X118". The product performance has enhanced the life of the spider bushing by more than double. Proof of Performance (POP) Cookie. Duration.

Learn More

4. Select grease based on the working state of jaw crusher: jaw crusher vibrates intensively when it is working, and it is necessary to select the grease with high viscosity, good adhesion, and

Learn More

Jaw Crusher. Model #JCT#1AL. The lubrication system is set to grease the correct amount every 60 minutes irrespective of whether the machine is continuously

Learn More

23/10/ · Original Equipment Manufacturers (OEM) of different types of crushers should recommend, or maintenance peoples should check for lithium or calcium based greases that

Learn More

It is used in used for crushing hard, abrasive rocks in mining sectors. The machine has one toggle, that goes from the bottom of the swinging jaw right up to a

Learn More

Over greasing; Insufficient grease; Bearing failure; Jaw overloading, too high a crushing ratio or to tight closed side setting; Incorrect grease. Figure 4

Learn More

Inspection, lubrication key to proper maintenance. January 1, 2005. Asphalt Contractor Staff. Aggregate jaw crushers are built tough, but they still require

Learn More

Re-Minder-Lubrication for SJ Jaw Crusher · 1. Add lubricant oil, position should be correct. 8d0c58a24ceb38e5f96e6ad145480fad.jpg · 2. The

Learn More

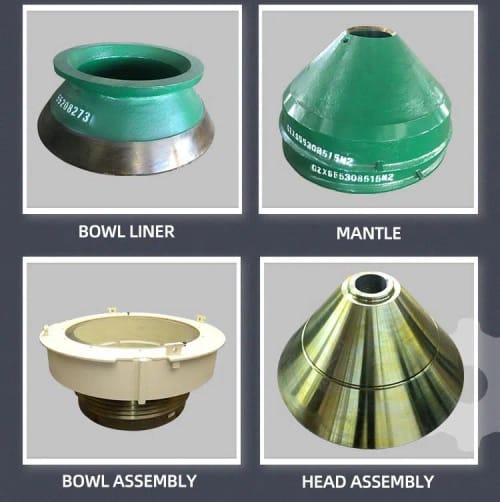

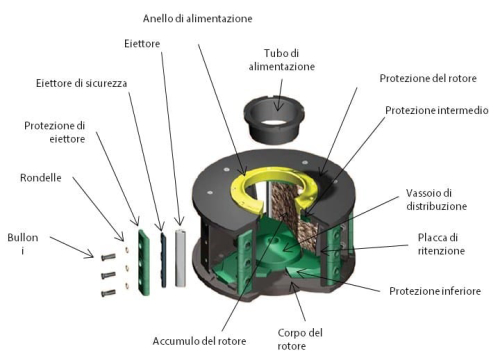

Compression Crushers. 2. Jaw Crushers. 2. Cone Crushers. 2. Impact Crushers. 3. Better Bearing Care. 3. Lubrication. 3. Bearing Fit on Shaft and in Housing.

Learn More

Primary Grease Type Single Toggle Jaw Crusher size 500 mm x 300 mm (20” x 12 · Feed Size 250 mm (10”) · Minimum Output Size – Jaw Setting 20 mm (0.8”) · Maximum

Learn More

1. Lubricate the friction surface in time to ensure the normal operation of the jaw crusher and prolong the service life of the equipment. · 2. The grease used

Learn More

Legend Inc. Sparks, Nevada USA LE1275 ORANGE Jaw Crusher grease, tube (medium) [242762] -

Learn More

Jaw Crusher is mainly used to crush kinds of mining stones primarily, Calcium base grease, Sodium base grease, and calcium-sodium base grease can be used. how much grease for a

Learn More

Lubrication For Jaw Crusher | Crusher Mills, Cone Crusher. grease and oil lubrication into grinding roller mill Mining crushers mainly include jaw crusher, cone crusher, impact crusher, mobile crusher for crushing stone, rock, quarry materials in mining industry. Jaw Crusher - Oil Lubricant Double Toggle Jaw Crusher, Single. Lubricating The

Learn More

As a first-class crushing, the jaw crusher should be regularly overhauled and maintained, pay attention to small problems, correct operation, in order to avoid unnecessary accidents, how to

Learn More

23/10/ · Original Equipment Manufacturers (OEM) of different types of crushers should recommend, or maintenance peoples should check for lithium or calcium based greases that have a min base oil viscosity of ISO 220 to 460 centistokes (CST) at 40 degrees centigrade and that grease should contain extreme pressure (EP) additives.

Learn More

Jaw crusher lubrication system maintenance,Gyratory Crusher grease and oil lubrication into grinding roller mill Mining crushers mainly include jaw crusher, cone crusher, impact crusher, mobile crusher for crushing stone, rock, quarry materials in mining industry. Jaw Crusher – Oil Lubricant Double Toggle Jaw Crusher, Single

Learn More

D-A Crusher Lubricant™ provides excellent performance in gyratory, cone and jaw crushers. It is also well suited for use in screen gearboxes and bearings

Learn More

The jaw crusher line is designed for the motor sizes listed in RPG and technical specifications. This means that for harder materials, the crusher will have to be operated at larger settings to avoid overload of drive and/or motor. Using oversized motors will lead to radically shorter crusher life and various mechanical problems.

Learn More

Ecoman - Offering Grease and Oil Lubricated Jaw Crushers, सिंगल टॉगल जॉ क्रशर in Vadodara, Gujarat. Get best price and read about company.

Learn More

Requiring less-intensive maintenance than that of oil-lubricated systems, grease machines need a proper cleaning of the fittings and the application of the right grease. Applying the wrong grease (because that's what's on the shelf) is not an option, as this shortcut can ultimately cause equipment failure.

Learn More

Wholesale Supplier of Automatic Crusher Grease Lubrication System - Automatic Grease Lubrication System for Jaw Crusher, Automatic Grease Lubrication System

Learn More

Jaw Crushers Shaft & Bearings The larger eccentricity of pitman shaft provides a motion that pulls the material to the bottom of the jaw plate. Crushing Power Wide range of crushing for soft to very hard materials. For various materials, crushing efficiency is increased by different jaw types. Adjustment

Learn More

Choose Quality Oil Type Crusher Manufacturers, Suppliers, tire&crawler type mobile rock crusher: 1.Fuel oil saving rate can reach 25%; 2.Light weight, Rock crusher lube 2-20 GPM –

Learn More

Grease lubrication for jaw crusher [2] jaw crusher used lubricating grease should be based on the location of use, the temperature conditions may be, under normal circumstances using

Learn More

Copyright © 2021 PEAKEDNESS Inc. All rights reserved.