Cone crusher maintenance critical to optimum output · CHOKE FEEDING IS A MUST · OIL LUBRICATION A PRIORITY · USE THE CORRECT OIL · INSPECT THE MAIN

Learn More

isc vsi rock crusher maintenance – process crusher. isc vsi rock crusher maintenance 13 Views. The is the professional mining equipments manufacturer in the world, located in China,India, along with other Asian

Learn More

Hp cone crusher operating manual africar 400 cone crusher instruction manual pdf cs cone crusher manual stone crusher installation cs cone crusher ch 440 cone

Learn More

This can be done through laying down a rock crusher maintenance schedule that is adhered to. Following are five steps to help achieve the goal. 1. Know and follow the Rock Crusher Constraints . Every machine has a few reservations and this applies to a rock crusher as well. There are basically three limitations that are particularly important

Learn More

Truck Technician. Job in Hillsboro - Washington County - OR Oregon - USA , 97123. Company: Pape' Truck Leasing, Inc. Full Time position. Listed on 2022-09-17. Job specializations: Maintenance/Cleaning. Mechanic.

Learn More

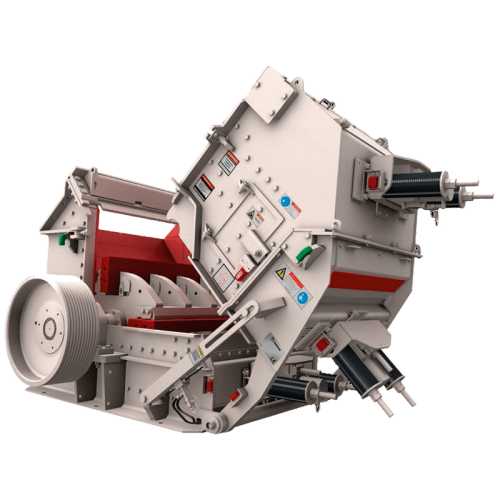

Rock Crusher Maintenance | Information on the Mining and Quarry Industries. There are many reasons why your impact crusher blow bars are breaking on a

Learn More

A daily visual inspection of the crusher is recommended. We this component depends on the application and the rock being crushed, therefore

Learn More

Performing regular maintenance on crushers is integral to the reliability, performance and output they achieve. Prevention is better than cure;

Learn More

Maintenance of Jaw crusher · Shut down the jaw crusher regularly and check the machine. Check the interior parts wear condition at regular intervals, such as

Learn More

SEPOR, INC. 718 N FRIES AVE. WILMINGTON, CA 90744. 310 830 6601. Fax: 310 830 9336 [email protected]. OPERATING AND MAINTENANCE MANUAL. MINI JAW CRUSHER

Learn More

Our factory and MSHA trained service team can come to your site, inspect our crushers and screens, train your employees on how to maintain equipment and replace parts or replace parts for you. Simply contact service today for more information on our ROCKSTAR inspection and maintenance program: [email protected] or call 610-273-2066 x 331.

Learn More

Inspection and maintenance of other parts Check whether the discharge port is blocked, remove the blockage in time, and keep the discharge unobstructed. Check whether the V-belt is loose. If it is too loose, you need tight it because loose belt will cause slippage. Whether the eccentric shaft is blocked.

Learn More

The regular maintenance and repair include adjustment of the gap between the rotor of the impact crusher and the impact lining plate, replacement of wearing parts,

Learn More

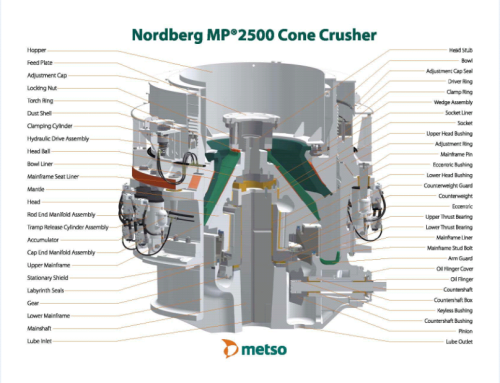

The crusher is the workhorse of the hard rock crushing industry. A gyratory crusher uses a mantle that gyrates (rotates) within a cone shaped inner surface.

Learn More

Check jaw dies daily, making sure bolts are kept tight. Check cheek plates for any excessive wear that may affect the mainframe of the jaw.

Learn More

Instead of using paper forms when running rock crusher watering system maintenance inspections, the app handles all of the details electronically. Simply open the app and run through each checklist item. The results of the inspection checklist can be used when scheduling preventive maintenance, crusher plant repairs and when performing daily

Learn More

Built on Condition Inspection, our Advisory Services program includes parts and maintenance planning and certified training. Get up to 15% more availability for your crushing and screening plant as you no longer need to wait for for the right parts (spares and/or wears). Advisory Services include: Monthly and quarterly inspections and reports

Learn More

Free telephone advice for maintenance and fault detection for the original sending specialized technicians to diagnose and repair Triaso® rock crushers.

Learn More

Maintaining Rock Crushers All rock crushers, especially the cone and jaw crushers commonly found in quarry operations, utilize steel crushing chamber liners fortified with the element manganese. The percentage of manganese in the steel depends upon the hardness of the material being processed and might look something like the following chart:

Learn More

Operating the crusher with a completely filled crushing chamber. Choking Stoppage of the flow of material through the crusher, which is usually due to the wet and sticky material clogging exit points. Circulating Load The amount of oversize material returned back to the crusher from a screen in a closed circuit crushing system.

Learn More

Aside from daily inspections, crusher maintenance used to be labor-intensive, hard work, especially when major components needed overhauling. "On gyratory crushers, we sometimes see damage in the upper rows of concaves from rock breakers being run on the concaves instead of rock," he added. Whatever the cause, damage must be evaluated

Learn More

Manual & Hand Operated Rock Crusher. HOW TO SETUP AND USE THE HAND OPERATED ROCK CRUSHER: The rock crusher is shipped with the handle screwed to the inside of the flywheel. This must be reversed. In the case of the double flywheel version there are two handles. The handle has two flats to accept a 24mm spanner right against the flywheel.

Learn More

Find Rock Crusher Maintenance Service Provider in Pune, Rock Crusher Maintenance Services in Vadgaon Sheri , Pune on bizzporto.com - Dhiman Industries.

Learn More

The regular maintenance and repair include adjustment of the gap between the rotor of the impact crusher and the impact lining plate, replacement of wearing parts, regular inspection of the hammer, lining plate, bearing temperature, etc. Replace badly wearing parts in time. Regularly inspect temperature of the rotor, motor and bearing, etc.

Learn More

All rock crushers can be classified as falling into two main groups. Compressive crushers that press the material until it breaks, and impact crushers using the principle of quick impacts to crush the material. Amortization, fuel, tires, and maintenance costs can be included when the vehicles are in high demand. In modern aggregates

Learn More

Rock Crusher Maintenance; How to maintain cone crusher; Jaw crusher for bulky waste and like matter; model 3858 jaw crusher; Cone crusher bowl adjustment mechanism;

Learn More

Copyright © 2021 PEAKEDNESS Inc. All rights reserved.