A hammer mill is a machine designed to crush material into smaller pieces by way of repeated blows from small hammers. Hammer mills work on

Learn More

The Working Principle Of Hammer Mills Stepbystep. 2020321A hammer mill is an essential machine in the pharmaceutical and food processing industries. You can use it to crush pulverie shred grind and reduce material to suitable sies. Even though there are many types of hammer mills the working principle is still the same.

Learn More

Hammer Mill Working Principle: The material to be crushed is fed from the top of the casing. The shaft is rotated at a high speed and centrifugal force causes

Learn More

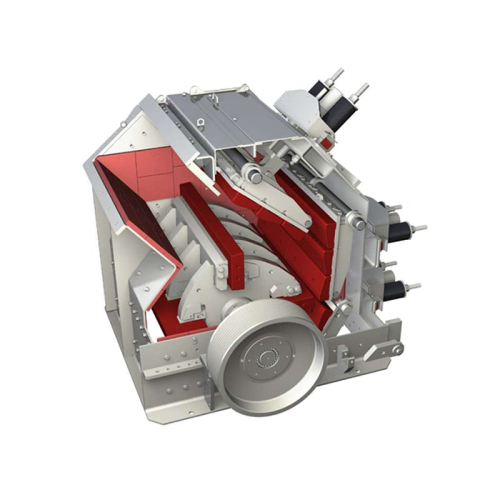

Hammer Mill Crusher & Grinder Sep 06, · An industrial hammer mill crushing rocks. The machine is configured using a motor to drive the engine and several rigids and joints for the hammers. The Working Principle of Hammer Mills (Step-by-step Guide) Jan 11

Learn More

A hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little hammers. These machines

Learn More

9 22 The machine is of hammer mill type. In this case, there is hammer like projection mounted on a shaft. The hammer revolves at high speed and grinds the

Learn More

12/5 · A hammer mill is a machine which break the material into small pieces by little hammer Hammer mill machine used in various industries including: Ethanol plants, Grain

Learn More

hammer mill machine supplier, with the production of this machine, help to many industries, to reduce the size of their product. working principle of hammer mill machine is reducing size. & it is so essential for Fertilizer & Animal feed industry.

Learn More

The Dixie (Non-Clog) Hammer Mill Crusher differs from all other hammermills in that its breaker plate, instead of being stationary, is a

Learn More

The operation of a hammer mill is simple. It has a cylindrical steel drum inside which hammers are mounted on a horizontal or vertical shaft.

Learn More

5/10 · Working of Hammer mill. The hammers are allowed to be in continuous motion (8000 to 15000 revolutions per minute). The feed material is placed into the hopper, which flows vertically down and then horizontally, while hammers are in continuous motion. These rotating hammers beat the material to yield smaller particles.

Learn More

12/11 · The uses of vertical hammer mill. Vertical Hammer Mill (We also called metal ball crusher machine, vertical mill, or vertical metal shredder)is used to pulverize materials in the extreme fineness

Learn More

operating principle of hammer mill The Working Principle of Hammer Mills (Step-by-step Guide . Even though there are many types of hammer mills, the working principle is still the same. You will learn about it shortly. First, let's have a quick over view of a

Learn More

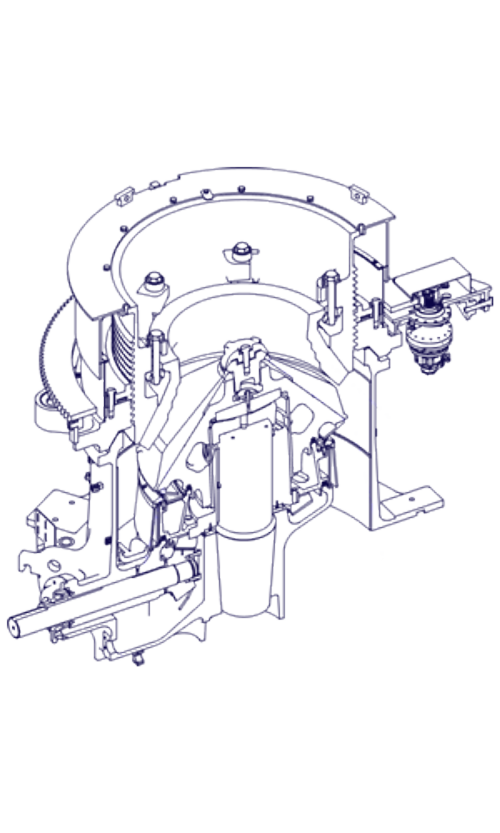

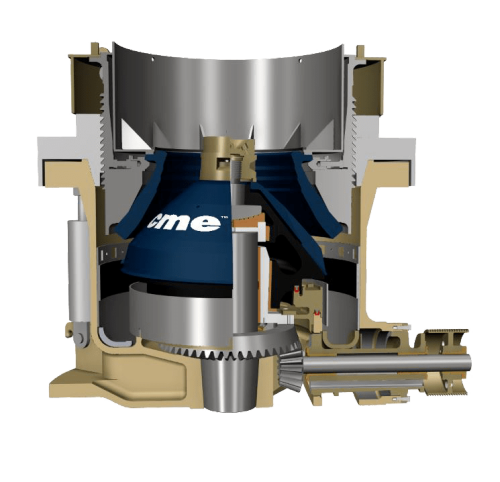

Hammer Mill Working Principle The hammermill, fundamentally, is a simple mechanism. The "orthodox" machine comprises a box-like frame, or housing, a centrally disposed, horizontal-shaft rotating element (rotor) on which the hammers are mounted, and usually a set of circumferentially arranged grates in the lower part of the housing.

Learn More

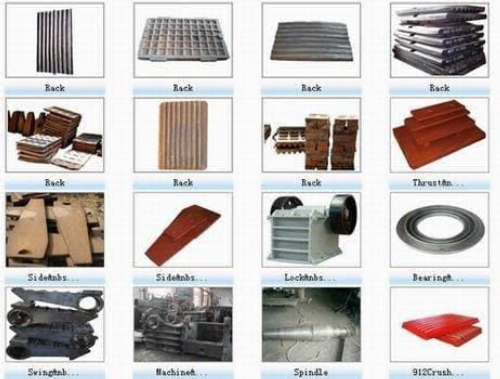

Work? Hammer mills work on the principle that most materials will crush, shatter or pulverize upon impact: The Process: • Material is fed into the mill's chamber through the . feed chute, typically by gravity. • The material is struck by . ganged hammers (generally rectangular pieces of hardened steel) which are attached to a . shaft

Learn More

Advantages of Hammer Mill: Hammer mill is easy to install, operate, dismantle and clean up. It occupies less space and can be easily placed in one corner of the manufacturing area. Various grades of material can be handled using screens of different sizes. It is versatile, and speed and screens can rapidly change based on milling requirements.

Learn More

Traditional hammer mills work on the principle that most materials will crush, shatter, or pulverize upon impact. Material is fed into the

Learn More

The working principle of the hammer mill is simple to understand. The principle is illustrated in Fig. 1 (a). It only requires choosing an appropriate motor, crushing hammers/knives and material to be crushed. It operates on the principle of impact between rapidly moving hammers mounted on the rotor and the stationary powder bed.

Learn More

Jul 05, · Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case. It produces size reduction by impact. The materials to be milled are struck by these rectangular pieces of hardened steel (ganged hammer) which rotates at high speed inside

Learn More

A hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little hammers. These machines hav

Learn More

Working principle of hammer mill machine pdf 2.5 Operating Principles Figure 2-1 illustrates the basic operating principle of the Prater Full Screen Hammer Mill. The G Series mill uses a shaped grinding chamber with distinct grind and release zones. Coarse material

Learn More

5). Design calculations and specifications of every component of the machine will be carried out after which the assembly of the components will be done. 6). A standard blue print ie assembly and component drawings will be produced. Based on these drawings, the construction of the machine will be carried out. 7).

Learn More

Mar 25, HAMMER MILL Principle The hammer mill operates on the principle of impact between rapidly moving hammer mounted on a rotor and the powder material. 11Fig Hammer mill 12. Working The hammers are allowed to be in continuous motion8000- 15000 rpm the feed material is placed into the hopper, whiles hammers are in continuous motion.

Learn More

Water Drop Hammer Mill Grinding and Milling Equipment 5.The rollers can work on both directions with slight vibration. 6.Energy conservation. The electricity consumption is 5.5 kwh, lower than average 6.7 kwh. Hammer Mill Working Principle. Raw material are fed

Learn More

High speed hammer mills (tip speed from 40 to 70 m/s) can allow to reach small particles sizes, below mm A universal mill is a derivation of the hammer mill

Learn More

Working Principle Of Hammer Mill Crusher. The company mainly manufactures mobile crushers, stationary crushers, sand-making machines, grinding mills and complete plants that are widely used in mining, construction, highway, bridge, coal, chemical, metallurgy, refractory matter, etc Product quality is life, and scientific innovation is motive power.

Learn More

Copyright © 2021 PEAKEDNESS Inc. All rights reserved.