The Rockmount Research and Alloys 11 Lb 5/32 x 14" Nickel Chromium Manganese Alloy Apollo B Stick Welding Electrode For Build-Up & Joining of All Steels can be

Learn More

Job Knowledge 98. The development and use of high strength low alloy (HSLA) steels has been driven by the need to reduce costs, the higher strength compared with a conventional carbon-manganese steel enabling thinner and lighter structures to be erected. The majority of these steels are to be found in structural applications; offshore

Learn More

For this purpose, a new steel alloy additive powder with medium manganese concept has been developed, which mimics the properties of automotive dual-phase steel. Starting with the welding of similar types of additive-powder-alloy, the combination of additive and conventional galvanized steel (HCT780XD) was considered for investigation. The

Learn More

New Features on Magnesium Alloys 122 loys. There are two binary systems employing manganese and zirconium (Oates, 1996). It is also common to classify magnesium alloys into those for room and elevated temperature applications. Rare earth metals and

Learn More

The average Welding Manager salary in Hillsboro, Oregon is $74,720 as of April 26, 2022, but the salary range typically falls between $65,613 and $86,368.

Learn More

Welding Techniques: Do not pre-heat. Use string or weave bead technique to deposit material. Avoid overheating on any manganese steel base metals. Welding

Learn More

If welding Manganese to carbon or alloy Use Covered Stainless Electrodes (AWS A5.4, E309) E-FeMn B Use High Speed GMAW and FCAW not SMAW If the Manganese has work-hardened in service (such as may likely be encountered in repair jobs), cut away the hardened surface. Then apply a "butter-coat" of 307 stainless.

Learn More

Welding Process: Stick Electrode ; Base Metal: Manganese Steel ; Application: Impact ; Size: 5/32" ; Type: Electrode.

Learn More

We provide alloy strips with thicknesses ranging from 0.01mm to 3.5mm, alloy wire with a diameter range of 0.009mm to 12mm, alloy rod over 5mm in diameter, and alloy sheet with widths under 1000mm. Our factory is fully equipped with a casting and melting furnace to fully control the quality of the materials. Index alloy strip, alloy wire

Learn More

Manganese steel plate can be welded, but it's important to keep the heat down and cool the weld as soon as possible to avoid cracking. An interpass temperature

Learn More

A method for welding alloys of high manganese content to avoid the development of weld flash is shown to comprise the steps of resistance welding the manganese alloy under conditions of temperature and pressure which are adequate for forcibly expelling

Learn More

A method for welding alloys of high manganese content to avoid the development of weld flash is shown to comprise the steps of resistance welding the manganese alloy under conditions of temperature and pressure which are adequate for forcibly expelling manganese oxide from the surface of the alloy. The resistance welding is performed while a thin layer of tin is disposed at the weld location

Learn More

Sections of cast manganese steel, or manganese steel to be interfaced to another steel, are joined by electroslag welding. Metallurgical limitations, operating parameters and physical attributes of the guide tube are imposed to retard embrittlement of the base metal

Learn More

A special heat treatment is required to provide the superior properties of manganese steel. This involves heating to 1850°F (1008°C) followed by quenching in water. In view of this type of heat

Learn More

7/10 · A too-slow travel speed increases heat input, which can burn alloying elements out of the metal and impact end-weld properties like strength, ductility and corrosion resistance. While a travel speed of 3 to 8 inches per minute is typical with other materials, welding stainless steel with flux-cored or metal-cored wires calls for travel speeds of 8 to 11 inches per minute.

Learn More

WELDING MANGANESE STEEL is not exotic or complex. The steel is just big and ugly, has a hard time making friends, and you need to respect some

Learn More

Manganese fumes are produced during metallurgical operations and several types of welding operations. The exposure can vary considerably depending on the amount of manganese in the welding wire, rods, flux and base metal. Confined space welding can significantly increase exposure to manganese fumes.

Learn More

Manganese steel plate can be welded, but it's important to keep the heat down and cool the weld as soon as possible to avoid cracking. An interpass temperature of below 500F is recommended. Because of the toxic nature of the weld fumes it's vitally important to protect yourself accordingly.

Learn More

The U.S. Department of Energy's Office of Scientific and Technical Information

Learn More

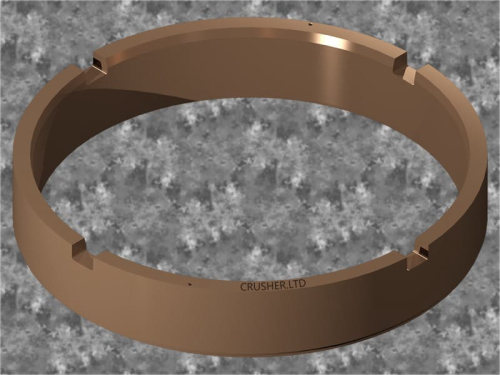

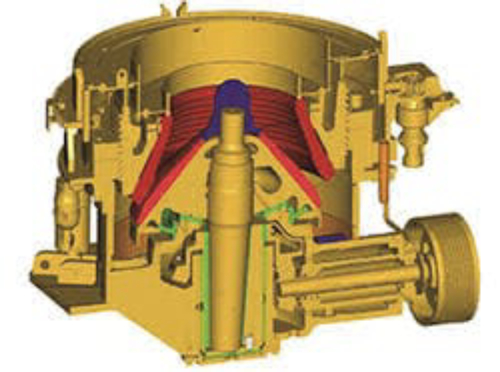

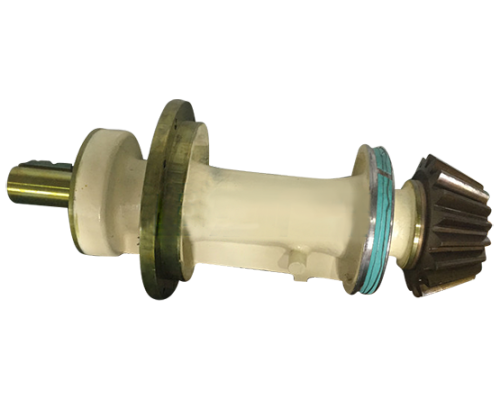

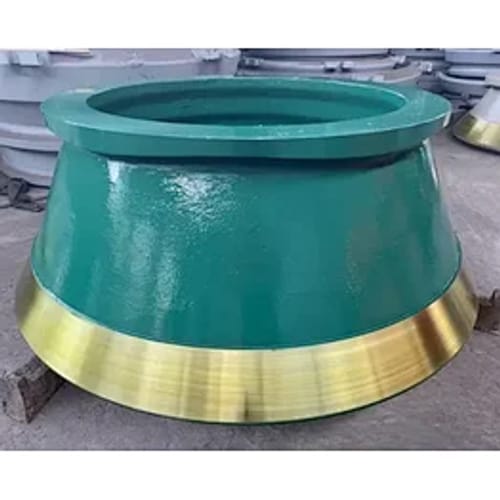

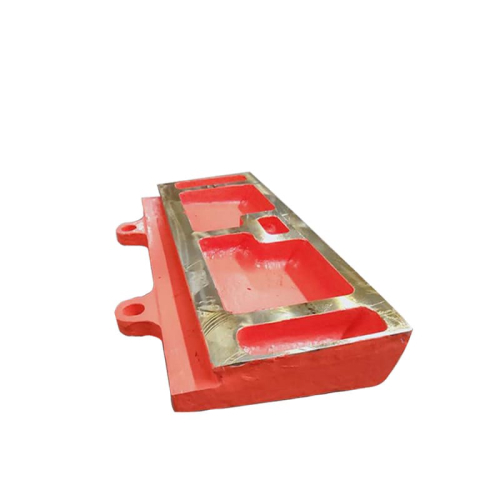

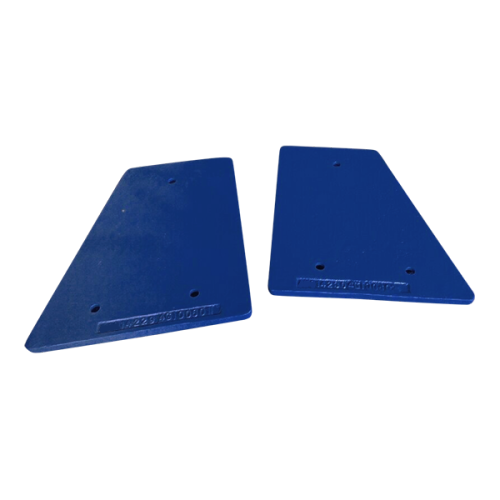

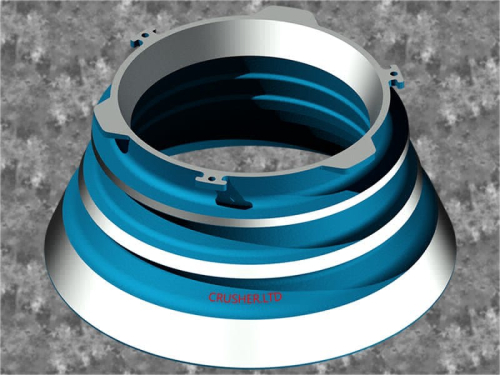

Carbon, low alloy and high manganese steel parts re-quiring protection from a wide range of severe abrasion and impact combinations: Typical examples are shovel buckets and teeth, crusher rolls, jaws, mantles and ham- flex-core welding wire for use with Stulz-Creusabro 4800 & 8000, Stulz Alloy/Wear products and other carbon steels. • Use

Learn More

Nickel alloys, both cast and wrought and either solid-solution-strengthened or precipitation-hardenable, can be welded by the GTAW process. The addition of filler is usually recommended. Direct current electrode negative (DCEN) is recommended for

Learn More

Steels with a range of 0.35% ‑ 0.6% carbon are heat treatable to higher strengths than mild steel but require special precautions in welding for this reason. These steels, usually also having a slightly higher manganese content (0.6‑1 %) are used for higher strength bar stock in machine frames, shafts, sprockets, and cast steel tractor

Learn More

Manganese steel built-up welding of the present invention with the chemical composition of the deposited metal of welding rod for (percentage by weight) is: C=

Learn More

Welding "Brass" is oft the case when rebuilding wornout or damaged ship propellers (this material is often called Manganese bronze in practice).

Learn More

N.W. 1KG aluminum manganese welding electrode flux shielded arc al alloy welding rod AL309 3.2mm 4.0mm ; Standard · GB / T3669E1100 AWS A5.3E1100 ; Description

Learn More

Depends on the application, but proper after weld peening will help minimize or eliminate weld cracking or warping. Austenitic manganese steel contracts

Learn More

Copyright © 2021 PEAKEDNESS Inc. All rights reserved.