Jaw Crusher Gap Setting. Jaw crusher machine are often used as primary coarse crushing equipment and are perhaps the most popular crusher worldwide. Primary jaw crusher are suitable for most any type of material. A jaw crusher is one of the main types of primary crushers in a mine or ore processing plant.

Learn More

On the initial set of new linings, put a mark on the change cap chauffeur ring where the pinion tooth reaches a chauffeur ring tooth when the target crusher setting has actually been achieved. Cone Crusher Cone Crusher 2 materials Conveyor Silo Tracker Conveyor Mining Decorations . Credits: FS Miner. 5/5 - (2 votes) Download mod. File File

Learn More

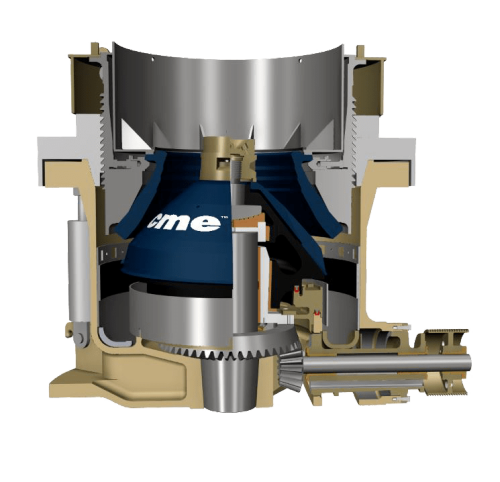

Cone crushers reduce material by compression, sizing material according to the gap setting. Intended for mining, construction aggregates, industrial and recycling applications, the durable Astec cone crusher lines are manufactured in various sizes, configurations and capacities to meet the demands of the competitive market. Crushing Jaw Crushers

Learn More

China cone crusher gap setting Manufacture, choose the high quality cone crusher gap setting from China We hold strengthening and perfecting our items and repair. At the same time, we get the job done actively to do research and progress for cone crusher gap setting organization associations and mates from all pieces of the entire world to call us and seek

Learn More

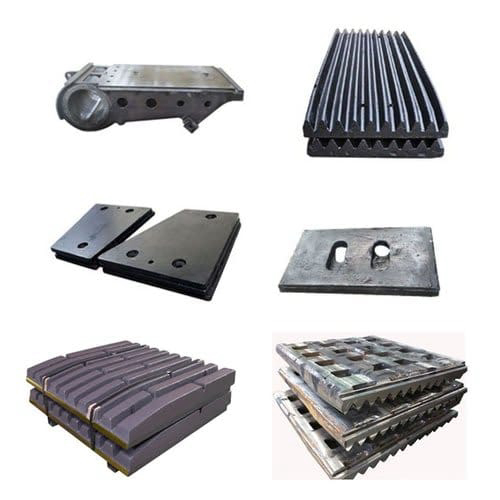

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for Jaw Crusher Labelled Diagram, Cone Crusher Spare Parts, High Mn Concave, Seeing believes!We sincerely welcome the new clients abroad to build organization associations and also hope to consolidate the associations while using the long-established prospects.

Learn More

A cone crusher is often used in the second to third crushing stage and The machine can also automatically adjust the crushing gap in an overload

Learn More

8. The outlet gap can be directly indicated by setting the pointer at 0 (zero) when the gap 1 is 0 (zero), and calibrating the scale in m/m unit according to

Learn More

Crusher gap setting – US Patent 4712743 Description Patent Description: TO THE INVENTION This invention relates to the measuring and setting of the crushing gap in crushers, such as gyrating disc or cone crushers. At

Learn More

is an automated closed side setting system for gyratory crushers that measures the gap between the concave and mantle.

Learn More

side setting of the crusher instead of opening of the crusher according to the needs of the plant. For further information, please refer to the equipment instruction manual - chapter 3 (general information on the crusher), item 3.7 (crusher adjustment). A CSS (A), OSS (B) and stopped (C) B C::: IC70C™ is a []

Learn More

4/28 · This article presents key tips that will help you maximize your cone crushing operation. 1. Operate at a consistent closed-side discharge setting. Producing a consistent product quantity, quality, uniformity and attaining a balanced circuit begins with operating the cone crusher at a consistent closed-side discharge setting.

Learn More

A crusher should be operated above 40% but below 100% rated horsepower in order to maximize cone crusher productivity and to have a proper "loaded bearing alignment". An optimal power range is to operate between 75%-95%. Operating a crusher above 110% rated power can cause premature crusher failure.

Learn More

Cone crushers are used in the mineral, mining, and aggregate industry for CSS adjustment based on information from the process. and, the gap.

Learn More

In large-size crushers with a diameter of the breaking head base of, say, 1750 to 2000 mm, the discharge gap can be as large as 100 mm, which corresponds to

Learn More

Mintap is the official worldwide distributor of the C-Gap closed side setting measurement tool for mining and quarrying clients. C-Gap enables operators to measure the closed side setting (CSS) of gyratory, jaw and cone crushers, to improve safety standards, production levels and costs. The C-Gap allows for the measurement of CSS’s between 7mm and 220mm

Learn More

the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different.

Learn More

Our high quality crusher parts are made for the HP Crusher 300 and 400 series, Gyradisc Crushers 36 48 54 66, and 2 3 4 4.25 5.5 7 Cone Crushers. Pièces de rechange - SCPM International Concassage

Learn More

2022/9/15 · About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features

Learn More

A Fritsch jaw crusher with maximal feed size 95 mm, final fineness (depends on gap setting) 0.3–15 mm, and maximal continuous throughput 250 Kg/h is shown

Learn More

China Cone Crusher Gap Setting Manufacture, Visit Here to Find the Cone Crusher Gap Setting That You are Searching for. Shenyang Sanland Mining Equipment Manufacture Co.,

Learn More

1/17 · The closed side setting can be calculated by deducting the stroke from the OSS. CSS is the most important crusher parameter since it defines the maximum product size and has

Learn More

A method for determining the adjustment of a crusher gap setting and/or crusher rate of wear in a gyratory crusher with hydraulic adjustment of the crusher cone height. The invention allows measurement of the gap while the machine is in motion and this data permits automatic adjustment during operation.

Learn More

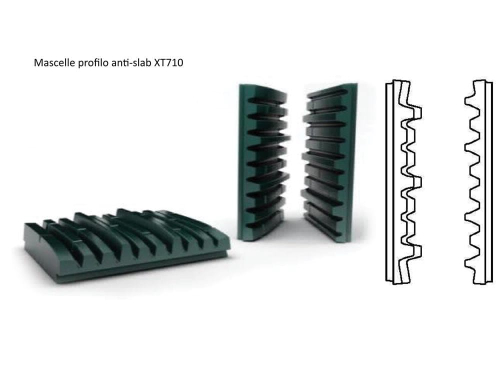

The open side setting is measured when the crusher is at rest. The setting is measured either top to top, or bottom to top, depending on the tooth profile of the jaw dies. Closed side setting (CSS) The closed side setting can be calculated by deducting the stroke from the OSS.

Learn More

How to set gap on cone crusher Which other method can I use to measure the gap for a cone crusher other than using the lead button method. We trying to avoid the health risks associated with the use of lead. I need a review if methods on how to measure a cone

Learn More

roll gap to the diameter), which was assumed to remain constant at any CSSl: closed side setting (CSS; mm) of the cone crusher for

Learn More

Cone Crusher Gap Setting We insist on offering high quality production with good business concept, honest sales and the best and fast service. it will bring you not only the high quality product and huge profit, but the most significant is to occupy the endless market for Cone Crusher Gap Setting, Heavy Mining Equipment Manufacturers , Sbm

Learn More

Copyright © 2021 PEAKEDNESS Inc. All rights reserved.